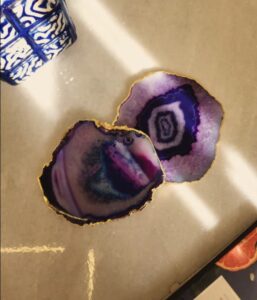

Agate Coaster

Agate Coaster Manufacturing Process – Natural Stone Craftsmanship

Agate coasters showcase the beauty of natural stone and skilled craftsmanship. Artisans begin the manufacturing process by selecting high-quality raw agate stones from trusted sources. First, craftsmen examine each stone for color depth, natural patterns, and structural strength to ensure premium quality.

Next, artisans cut the agate stones into precise coaster shapes using advanced cutting tools. They maintain uniform thickness to provide stability and balance during daily use. At the same time, they preserve the natural banding and crystal formations that make each agate coaster unique.

After that, craftsmen polish the surface carefully to achieve a smooth and glossy finish. Polishing enhances the stone’s natural shine and highlights its layered appearance. Additionally, artisans shape and smooth the edges by hand to create a safe and refined product.

Then, the manufacturing team attaches a protective backing to the base of each agate coasters. This backing protects furniture surfaces and improves grip. Moreover, quality experts inspect every coaster for surface clarity, edge finishing, and durability.

Finally, artisans clean and prepare the agate coasters for finishing touches. Some designs receive gold or silver edge detailing to add a premium decorative appeal. Each coaster maintains its natural look, which ensures no two pieces appear exactly the same.

Overall, agate coasters offer excellent heat resistance and moisture protection. People use them for hot beverages, cold drinks, office tables, dining spaces, hotels, and gift collections. Therefore, agate coaster manufacturing delivers durable, elegant, and visually striking products that enhance any interior setting